Central Vis-Tex System

The Gurtler Vis-Tex Central System is a uniquely engineered liquid product injection system designed to serve your entire wash aisle, up to 10 conventional washers or washer extractors, with up to 10 different liquid products.

- Fast: High speed injection reduces wait times and improves production efficiency.

- Reliable: Metering system has no moving parts for maintenance-free performance.

- Accurate: Unique patent-pending inductive meter technology assures the right amount of product every time.

The Pump Module is the fastest in the market based on a comparative field study. Plus Dual-System Redundancy reduces hold time and increases productivity. Major benefits include the space-saving design; ease of installation; extremely durable pumps; accurate measuring technology and more. Two sizes available, Model 1500 for larger washers and Model 750 for smaller washers.

The Pump Module is the fastest in the market based on a comparative field study. Plus Dual-System Redundancy reduces hold time and increases productivity. Major benefits include the space-saving design; ease of installation; extremely durable pumps; accurate measuring technology and more. Two sizes available, Model 1500 for larger washers and Model 750 for smaller washers.Specifications

- Number of Pumps: One delivery pump

- Type of Pump: Bolted, air operated double diaphragm

- Chemical resistant polypropylene/Teflon diaphragm; all wetted parts chemically resistant

- Space Requirement:

- 1500: 30″ L x 34″ W x 75″ H

- 750: 44″ L x 24″ W x 80″ H (can be wall mounted)

- Construction:

- 1500: 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure

- 750: Stand is 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure

- Voltage: 110v.

- Air Requirements:

- 1500: 6-12 cfm @ 60-80 psi

- 750: 3-5 cfm @ 60-80 psi

- Air/Chemical Lines:

- 1500: All lines routed to central trunk in rear of system

- 750: All lines routed to central from bottom of system

- Hot, cold or tempered water @ 8 GPM

- Flow Rate:

- 1500: 5-8 GPM

- 750: 2-3.5 GPM

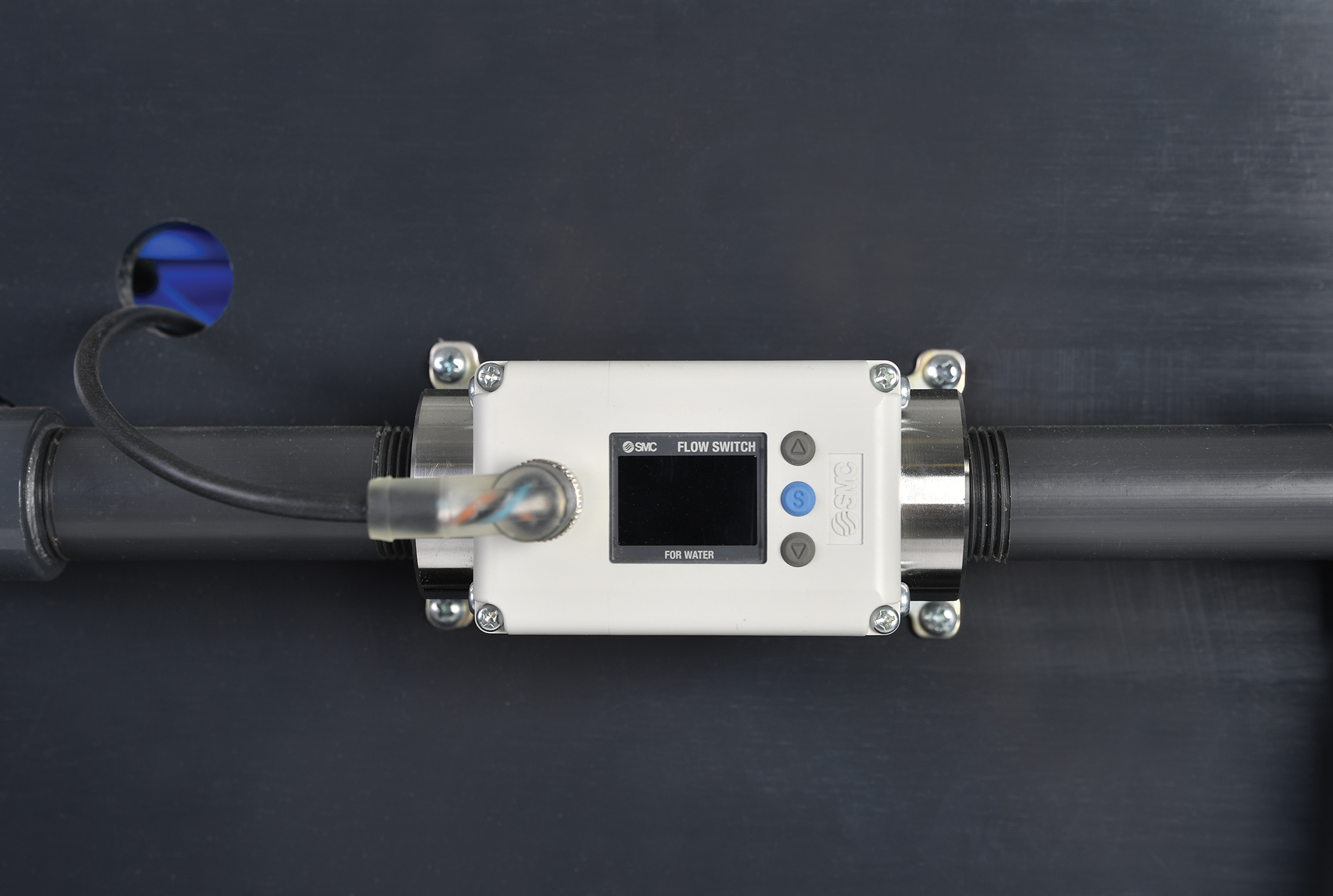

The Vis-Tex Central utilizes unmatched flow-metering technology. Gurtler’s unique meter has no moving parts and measures chemical injections based on the conductivity of each product; delivering accurate injections, real time alarms, and the fastest injection times. Assures that every chemical injection delivers the right amount of chemical, at the right time, every time!

The Vis-Tex Central utilizes unmatched flow-metering technology. Gurtler’s unique meter has no moving parts and measures chemical injections based on the conductivity of each product; delivering accurate injections, real time alarms, and the fastest injection times. Assures that every chemical injection delivers the right amount of chemical, at the right time, every time!Specifications

- Chemicals are flushed after every measurement

- Alarms for No Product, No Flush Water, Low Air Pressure and more

- Valve Type: Air-operated, diaphragm

- Valve Construction: Chemically resistant polypropylene/Teflon

- Voltage: Low: 24v.

- Calibration tube for verifying accuracy

- Programmable injection priority

- Washer hold capability

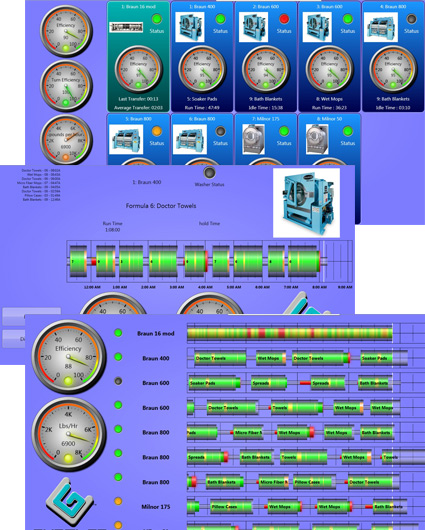

Exceptional and customizable reporting package – all your production metrics. The Data Center provides a comprehensive data management capability: Complete wash floor overview; real-time monitoring; customizable goal tracking dashboard; efficiency monitors and trend charts; fully customizable production reports, and more.

Exceptional and customizable reporting package – all your production metrics. The Data Center provides a comprehensive data management capability: Complete wash floor overview; real-time monitoring; customizable goal tracking dashboard; efficiency monitors and trend charts; fully customizable production reports, and more.Specifications

- Remote web access and control

- Automatic e-mails or text messages for alarms

- Network to any computer

- Computer: Fanless industrial PC

- Monitor: 23″ touch screen