Tunnel Vis-Tex System

Gurtler has the vision to make your tunnel operation run at maximum efficiency

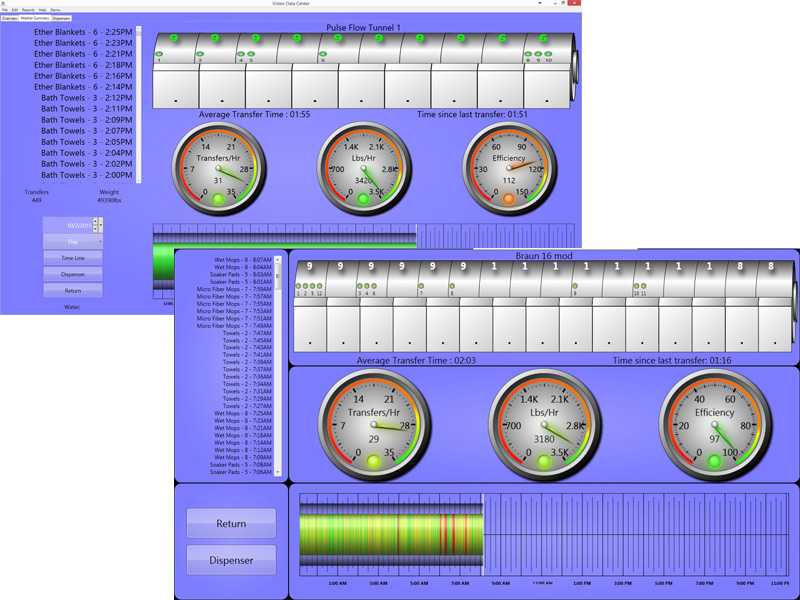

The Gurtler

Vis-Tex Tunnel System features our uniquely designed space-saving

Pump Module with more pumps to allow for the greatest flexibility for your chemical usage, meaning the best possible results with the lowest possible cost. Durable, new design diaphragm pumps require minimal service – can operate for 5 million strokes with no maintenance. Gurtler’s exclusively engineered

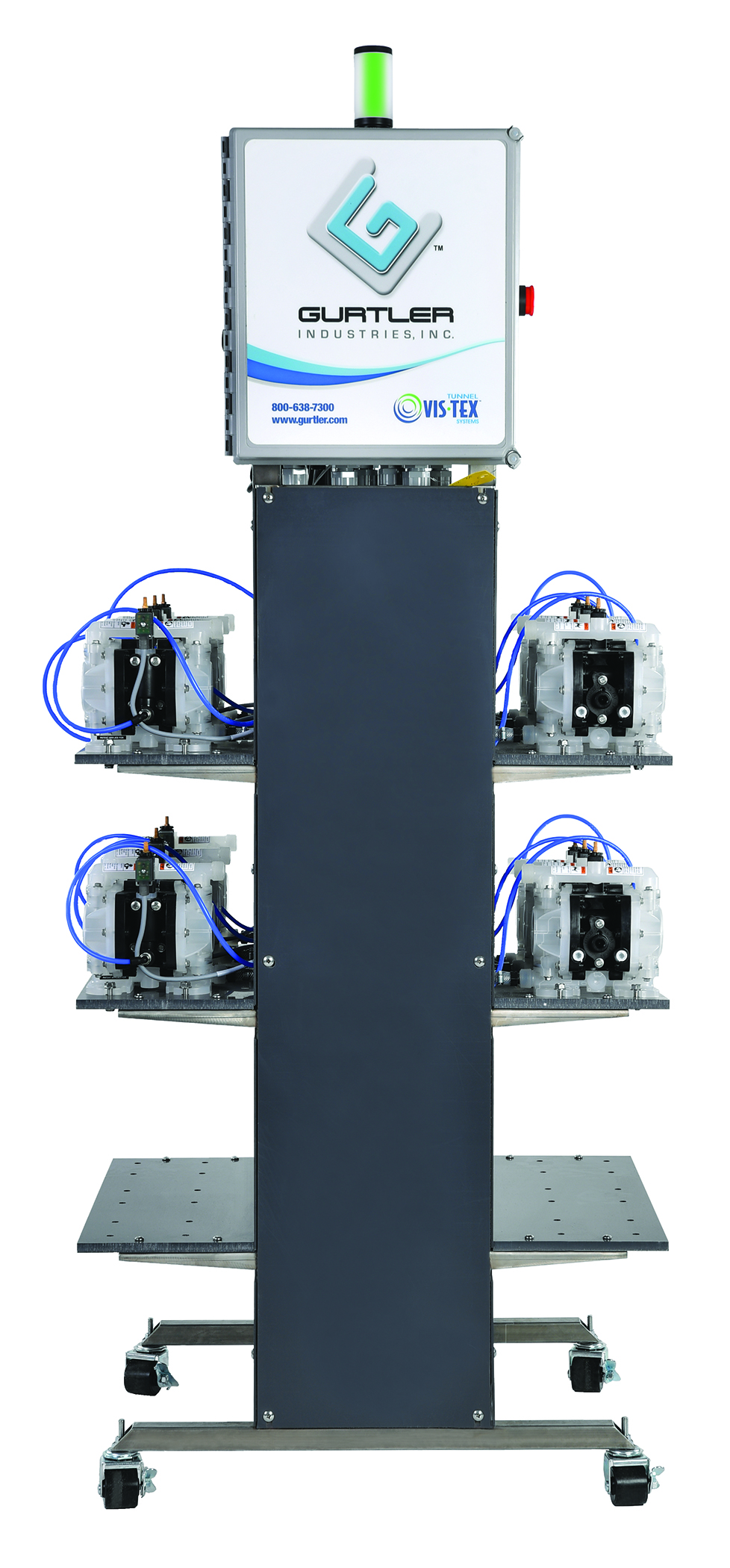

Injection Module automatically calibrates the product injections to assure precise and accurate measurement of chemical usage, every time, all the time. This reliable and robust system mounted at the tunnel chemical injection point delivers real volumetric proof of injection results. Calibrations can be performed without manual intervention. This technology enhances safety while delivering consistent performance and quality. Plus, Gurtler’s

Injection Module now has an optional metering system for product injections to assure precise and accurate measurement of chemical usage. Three value-added points: Proof-of-flow, Proof-of-delivery, and Metered validation of every injection. The

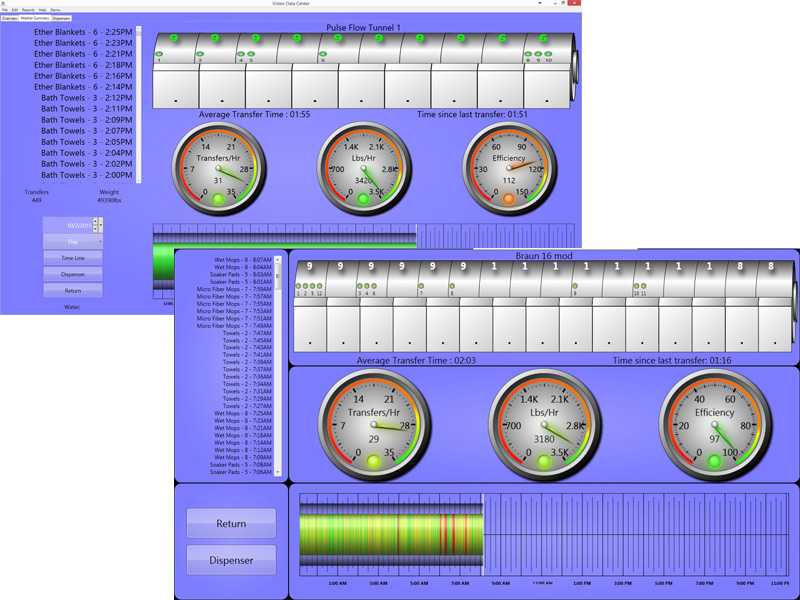

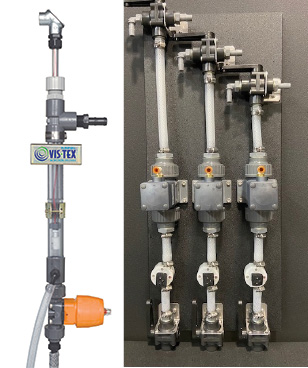

Data Center features email/text alarm and reporting capability. Fully customizable reports include production reports, turn times, chemical usage and more. Dashboard is customizable to allow for quick goal-tracking information. Networked system allows remote monitoring for maximum impact. Plus, the system is compatible with the Gurtler

Vis-Tex Central System software, so a complete wash room productivity analysis can be obtained, and displayed on managements’ desktop computers, tablets and mobile devices. Gurtler’s

Vis-Tex Tunnel System reflects the commitment that we have for the market. Gurtler and our Technical Specialists understand what a tunnel operation needs to operate at high efficiency, and our newest system incorporates all the features that will make that a reality.

The

Pump Module features include a space saving design, ease of installation, extremely durable pumps and unitary construction, direct injection into the tunnel, instant chemical injection, with no flushing or dwell time, free standing unit, protected and hidden injection tubing lines and cables, easier to service and easily accessible components.

Specifications

- Number of Pumps: 18 total; up to 16 chemical pumps plus 2 auxiliary pumps (optional flushes)

- Type of Pump: Bolted air operated diaphragm (AOD)

- Chemical resistant polypropylene/Teflon (where required) diaphragm. All wetted parts chemically resistant.

- Space Requirement: 63.5″ H x 35″ W x 22.5″D

- Construction: 304L stainless steel frame, polycarbonate shield, Schedule 80 chemical resistant PVC mounting shelves

- Voltage: 110v.

- Air Requirements: 3-5 cfm/pump (up to 18 pumps or 108cfm) @ 60-80psi

- Air/Chemical Supply Lines: All lines routed to central trunk in rear of dispenser

- Pump Life: >5 million strokes or >48,000 gallons pumped with no problems or maintenance

The best chemical injection system for tunnels just got better.

Gurtler’s exclusively engineered

Injection Module now has an optional metering system for product injections to assure precise and accurate measurement of chemical usage. The tunnel injection system uses the newest in construction materials for prolonged use-life and faster chemical injection with no delays. Three Value Added Points:

- Proof-of-Flow

- Proof-of-Delivery

- Metered Validation of Every Injection

The traditional

Injection Module offers three points of validation: Proof-of-Flow, Proof-of-Delivery, and Automatic Calibration. The systems’ ability to

automatically calibrate is unmatched within the industry. Now, calibrations can be performed without manual intervention! This technology enhances safety while delivering consistent performance and quality.

Specifications

- Space Requirements: 18-24 inches tall depending on model, 1-½” diameter per unit

- Construction: Schedule 80 chemically resistant PVC

- Valve Type: Air operated diaphragm valve

- Valve Construction: Chemically resistant polypropylene/Teflon

- Voltage: Low (<12 volts)

- Calibration Frequency: Programmable from every injection to once every production shift

- On-the-fly adjustments

- Manual override function

- Temperature compensation

The

Data Center features a touch-screen programming monitor with full alarm and reporting capability. Fully customizable reports include production reports, chemical usage, and more. Our system is compatible with the Gurtler

Vis·Tex Central System software, so a complete washroom productivity analysis can be obtained, and displayed on managements’ desktop computers, tablets and mobile devices.

Specifications

- Complete wash floor overview

- Real-time tunnel washer monitoring

- Customizable goal tracking dashboard

- Efficiency monitors and trend charts

- Fully customizable production reports

- Individual and independent pump control

- True proof of chemical delivery

- Default pumping mode if major calibration is required (“soft” alarm)

- On/Off calibration master switch for each pump

- Customizable calibration range for each pump/product

- Web server database and 24hr onboard data storage

- Remote web access and control

- Automatic e-mails or text messages for alarms

- Bulk/Day tank chemical level monitoring

- Controlled by on-board CPU (not PLC)

- Network to any computer

Advantages

- Monitor all processes simultaneously

- Instant verification of process

- Monitor daily production goals in real-time

- Track changes in production over time

- Detailed reports on all production parameters

- Set different calibrations for each pump; one pump alarm/failure doesn’t effect the rest

- Assurance that chemical reaches wash wheel

- Turn calibration system on or off

- Match calibration to characteristics of chemical being pumped

- Monitor all wash floor processes from dashboard

- Data integrity maintained on a secure server and backed up on unit

- Monitor and make changes to system from any web connection

- Instant notification of system alarms

- Precise knowledge of chemical inventory; calculate days until empty

- Fast processor, large data storage, powerful computing power

- Monitor system from anywhere in plant

Back to Injection Systems

The Pump Module features include a space saving design, ease of installation, extremely durable pumps and unitary construction, direct injection into the tunnel, instant chemical injection, with no flushing or dwell time, free standing unit, protected and hidden injection tubing lines and cables, easier to service and easily accessible components.

The Pump Module features include a space saving design, ease of installation, extremely durable pumps and unitary construction, direct injection into the tunnel, instant chemical injection, with no flushing or dwell time, free standing unit, protected and hidden injection tubing lines and cables, easier to service and easily accessible components.

The Data Center features a touch-screen programming monitor with full alarm and reporting capability. Fully customizable reports include production reports, chemical usage, and more. Our system is compatible with the Gurtler Vis·Tex Central System software, so a complete washroom productivity analysis can be obtained, and displayed on managements’ desktop computers, tablets and mobile devices.

The Data Center features a touch-screen programming monitor with full alarm and reporting capability. Fully customizable reports include production reports, chemical usage, and more. Our system is compatible with the Gurtler Vis·Tex Central System software, so a complete washroom productivity analysis can be obtained, and displayed on managements’ desktop computers, tablets and mobile devices.